The Ultimate Guide to Water Tank Fittings & Connectors: Ensuring a Leak-Proof System

Water is an indispensable resource in our daily lives, and effectively managing and storing it is paramount. Central to this objective is water tanks’ role and, more specifically, water tank fittings and connectors. This guide will enlighten you on these critical components, enhancing your knowledge and ability to maintain a high-performing, leak-free water system.

Table of Contents

ToggleUnderstanding Water Tanks

The role and importance of water tanks in daily life

Water tanks are a crucial part of our lives, storing water used in many day-to-day activities such as drinking, cooking, bathing, and irrigation. With them, our access to this precious resource would be consistent and reliable.

Types of water tanks and their uses

There are numerous types of water tanks, including plastic, concrete, steel, and fiberglass. Each has unique benefits for various uses, from residential to commercial applications.

The role of fittings and connectors in water tanks

Fittings and connectors play a crucial role in the function of water tanks. They secure the connections between pipes, tanks, and other components, preventing leaks and ensuring efficient water flow.

The Basics of Water Tank Fittings and Connectors

Definition and functions of water tank fittings

Water tank fittings are hardware pieces that connect a water tank system. They include valves, outlets, and caps, among others, essential for controlling the water flow.

Definition and functions of water tank connectors

Conversely, connectors are tools used to join different sections of piping in a water tank system. They serve to establish a leak-free and secure pathway for the water to travel from the tank to its final destination.

The relationship between fittings and connectors in water tank systems

Fittings and connectors work in tandem to create a secure and functional water tank system. While connectors join the pipes, fittings ensure that the system is adaptable and can be controlled to match the user’s specific requirements.

Types of Water Tank Fittings & Connectors

Overview of different types of fittings and connectors

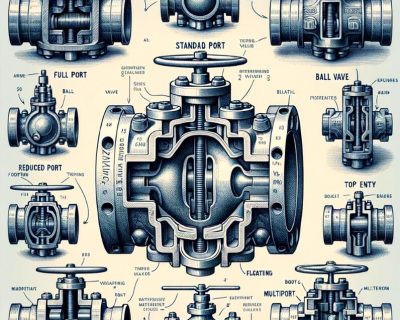

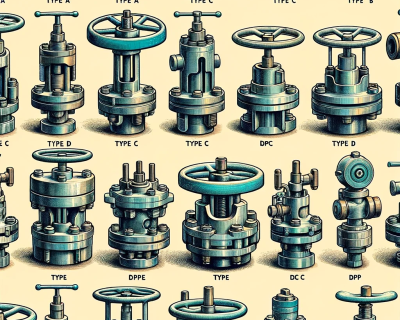

Various types of fittings and connectors are available in the market, each designed to perform a specific function. These include elbow connectors, T-connectors, ball valves, stop valves, and more.

A detailed description of each type, its usage, and compatibility with different water tanks

Elbow connectors alter the pipes’ direction, while T-connectors allow flow splitting. Ball valves offer control over the flow, and stop valves can stop the flow when required. The choice of these components depends heavily on the design and requirements of your water tank system.

Choosing the Right Fittings and Connectors for Your Water Tank

Factors to Consider When Choosing Fittings and Connectors

Multiple factors influence the choice of fittings and connectors for your water tank. These include the type and size of your tank, the intended usage of the water, environmental factors, and the material compatibility of the fittings and connectors. For instance, a connector made of a material that reacts with the tank material could lead to leaks, rendering the tank inefficient.

Matching Fittings and Connectors to Different Types of Water Tanks

It is essential to consider the type of water tank when selecting fittings and connectors. For example, plastic tanks often require different fittings than steel or concrete tanks due to the material’s flexibility and strength differences.

The Importance of Material and Quality in Fittings and Connectors

The quality and material of fittings and connectors significantly impact the lifespan and efficiency of your water tank. High-quality fittings and connectors made from durable materials like brass, stainless steel, or high-density polyethylene can withstand harsh environmental conditions, resist corrosion, and prevent leakages, providing long-term reliability.

How to Install Water Tank Fittings and Connectors

A Step-by-Step Guide to Installing Fittings

Installation of fittings begins with planning the layout based on the tank’s design and application. Once planted, drill holes at the marked locations, insert the fitting, and tighten it accordingly. Always ensure the fittings are securely tightened to prevent leaks but avoid over-tightening, which can cause damage.

A Step-by-Step Guide to Installing Connectors

Connectors are installed similarly to fittings. Start by identifying the pipes’ connection points, then install the connector, ensuring a snug fit. You might need Teflon tape to ensure a leak-proof seal if using threaded connectors.

Common Mistakes to Avoid During Installation

Common mistakes during installation include:

- Over-tightening of fittings, resulting in cracks or damage.

- Using incompatible materials, which can cause reactions and corrosion.

- Proper alignment of fittings and connectors can result in leaks or efficient water flow.

Safety Precautions During Installation

Safety is paramount when installing water tank fittings and connectors. It is important to use the appropriate tools for the job and wear protective gear like gloves and safety glasses. Additionally, ensure safety by ensuring the work area is free from any potential hazards. If in doubt, always consult a professional.

Understanding the importance and right usage of water tank fittings and connectors is key to ensuring a robust and efficient water storage system. While this guide provides comprehensive knowledge, remember that every water tank setup is unique, and the best practices may vary accordingly. Always prioritize quality and compatibility when selecting your fittings and connectors, and don’t hesitate to seek professional help if needed. Having the proper expertise and equipment makes it possible to construct a durable water tank system.