With growing consumer needs for gas and oil, petrochemical, and refining products, the demand for fast expansion and growth of new units as well as production facilities grows. Also, this increased the demand for third party equipment manufacturers to help with construction. OEM provides many perks to end users planning to grow and make their production bigger. From big capital projects to fast turnarounds, today’s OEM can be found in each part of the supply chain.

We support the manufacturer by stocking OEM valves. Our dedication to quality and our capability to develop and handle a multinational chain have permitted us to move fast with the market’s demand from OEM.

We are known as one of the premier providers and suppliers of OEM ball valves. We have a fantastic reputation in providing customized products as well as OEM service. Buy high-quality OEM ball valves from us.

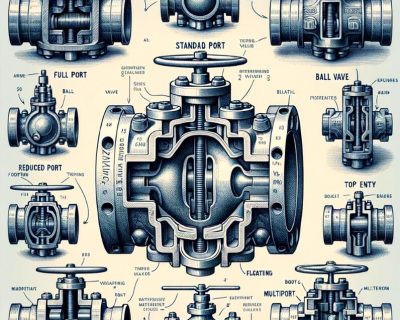

What is an OEM Ball Valve?

An OEM ball valve takes account of a valve body wherein a big sphere with a hole in the middle the same to the inside diameter of the pipe. During the ball’s rotation in the open position, the valve gives the conduit or complete bore needed for unlimited liquid flow and pigs or scrapers.

Unlike other types of valves, this one has a minor resistance to flow in the open position. Once totally open, it has a 3.0 L/D ratio. This type of ball valve is utilized in the fully open or fully closed positions. Compared to gate valves, an OEM ball valve needs a one-quarter turn of the hand-wheel to change to fully closed from being in a fully open position. Such fast closing and opening of an OEM ball valve might be of significance in some fittings where isolating pipe parts instantly are needed in case of urgent situations.

Where to Use OEM Ball Valves?

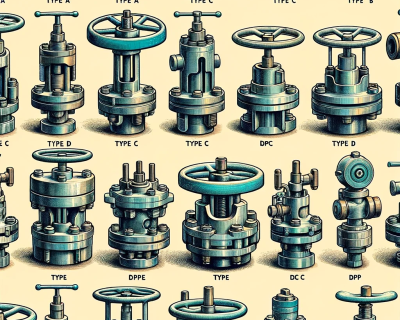

Our high-quality OEM valves are utilized for on and off and throttling services. They are identical to plug waves but makes use of a ball-type seating element. This is a fast opening, and when opening and closing, it only needs one quarter. They also need power or manual operators in big sizes as well as high operating temperatures to overcome operating torque. This is armed with soft seats that conform voluntarily to the ball surface and comes with a secondary metal seal. Once it is left partially open for a prolonged time in a high pressure drop in the ball, the soft seat might be harmed and might lock in position. This is ideal for stopping as well as starting flow; however, it might be utilized for reasonable throttling.

Benefits of Our OEM Ball Valves

Our OEM ball vales are the most sought-after fluid shutoff valve in gas facilities and upstream oil companies, both offshore and onshore. Also, they are utilized in the fuel gas system feeding furnace. Our OEM ball valves have many perks such as:

- High pressure resistance

- Compact assembly

- Fast closing and opening

- Can be actuated easily

- Easy maintenance

- Pigging operation

- Low pressure drop

- Adopted to diverse hydrocarbon stages encountered such as gas, liquid, and mixture

Choose Our OEM Ball Valves for the Next Project

We supply finished valves to the gas and oil, pulp and paper, refining as well as petrochemical industries, which are supported by OEM all over the world.

Common OEM ball valve settings, using our products, take account of Meter Skids, Slug Catchers, Gas Dehydration and Scrubber Packages, Compressor Skid, Fractional Units, as well as Stem Boilers, Burners, and even Heat Recovery Systems.

For more details, please feel free to contact us now about our products!