Check valves are dual-port valves that have two openings in the system of the valve. The first opening is intended for gas, fluid, or oars to come to the valve in the inlet port. The second opening, on the other hand, is designed for the media to go out of the valve or exit port. Spring check valves, like other types of check valves, need no external control to function and work. This possesses similar basic style elements as other types of check valves.

Our spring check valves offer a consistent and precise fluid control. This avoids the reversal flow in the piping system. Our spring check valves are perfect where back-flow can potentially harm filters, pumps, and process equipment. This works without needing adjustment and settings. The line forces the plastic cone off the Elastoplast seat. Once the flow ends, spring moves back the cone onto the Elastoplast seat, which stops the flow. It has a spring that is made from high-grade steel.

The valves we offer comes with real union design, which enables fast elimination from the piping system with no breaking down the connections of the piping. Unscrew the dual assembly nuts, then raise the body of the valve out of line. Our spring check valves are ideal for cost sensitive’s purposes and no compromise value.

Features of Our Spring Check Valves

- Our spring check valves come with essential features such as:

- Fast installation process

- Easy to maintain

- Rugged and cost-efficient style and design

- Might be utilized horizontally or vertically

- Silicon free construction

Characteristics and Uses of Spring Check Valves

There are amazing characteristics and uses of our spring check valves; this takes account of the following:

- Keep your equipment safe and sound from damage due to back-flow

- Offer pressure relief for the safety of the system

- Avoid contamination from reverse flow

- There no human control or intervention needed in order to work

- Run and powered by flow as well as differential pressure with help from spring pressure.

Advantages of Spring Check Valves

There are a lot of perks of spring check valves, such as fast stream disruption. They offer beneficial sealing at a low temperature as well as at a low valve pressure. The idea of working on this product doesn’t get affected by the back-flow or gravity pressure to work properly. The close depends on vertical orientation and avoids gas or fluid back-flow during maintenance.

Other Benefits

- Offers quick flow interruption

- Offers positive sealing

- Doesn’t need gravity to actuate and function

- Able to accommodate wide ranges of temperature

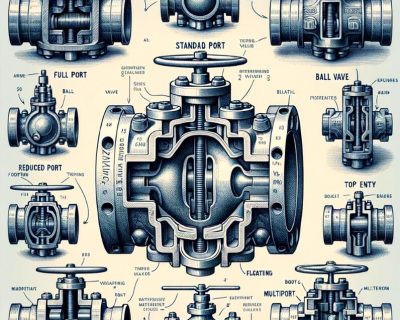

Spring check valves are normally set up in line with process piping. The body of the valve is hollow and has a cross-sectional element, with a hole or passage in it.

The sear separates the valve into the outlet or downstream and upstream or also known as an inlet. A large stopper of many types rest inside it and is able to move in order the surface to rest opposed the seat of the valve. The position of the spring applies a constant force which holds the surface of the valve sealing together.

For further details regarding our spring check valves, you are very welcome to give our customer hotline numbers a call. For orders, you can visit our site and fill out the online form.